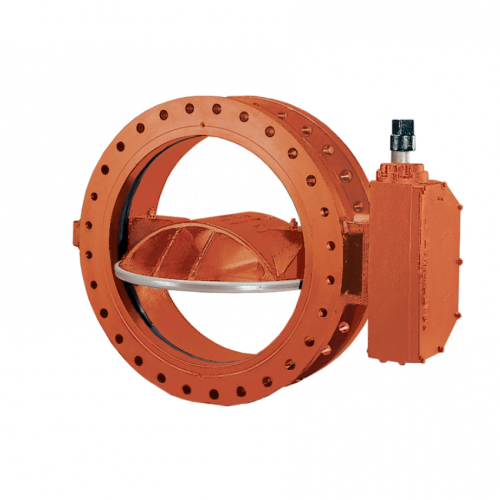

3″ – 48” Butterfly Valves (Class 150B) Designed specifically for the waterworks industry, Lineseal® butterfly valves offer the ruggedness and reliability required for buried service and performance. Lower head loss means getting the most from your pumping station dollar. Lower torques mean less costly actuation packages and the maintenance-free design helps keep your budget under control.

Mueller Lineseal Butterfly Valve Specifications:

- Meets or exceeds all applicable requirements of ANSI/AWWA C504 Standard Class 150B; NSF 61 certified

- Buried service valves: I.D. and O.D. coated

- Body – Cast Iron ASTM A-126

- Flanges drilled per ANSI B16.1 Class 125

- Above ground valves (ordered with either a hand wheel, position indicator on the actuator, or lever): minimum 8 mills epoxy coated interior and exterior; meets AWWA C504 standard

- Seat-in-body design reduces seat failure due to corrosive buildup in the valve and pipeline

- Through-disc pinning provides a tight disc-to-shaft pin connection, greatly reducing the possibility of loosening through vibration

- The disc edge is 316 Stainless Steel

- Disc – Cast Iron ASTM A-126 (3″, 4″, 6″ Stainless Steel ASTM A351 CF8M)

- Symmetrical disc for higher Cv and lower head loss

- Nonmetallic bearings prevent galvanic corrosion and provide a lower coefficient of friction

- Chevron “V” type packing is self-adjusting to last the life of the valve

- 3″-24″ Standard 304 SS hardware

Case Study – Lineseal Butterfly Valve installed- Mueller Butterfly Valve Case Study