The Hydro-Guard® Automatic and S.M.A.R.T. Flushing product family offers industry-leading, reliable designs to address a range of utility needs and community concerns. Traditional routine flushing programs can mitigate community drinking water concerns related to taste, discoloration, or odor; however, manual hydrant flushing can be costly and time-consuming for utilities along with causing wear on the hydrant. Automated flushing programs can address these issues while also considering climate, environmental, installation, and community concerns. Each product series is available in a cold climate or warm climate edition and supports a range of popular bury depth options to ensure year-round performance in any distribution network. In addition, Hydro-Guard Automatic and S.M.A.R.T. Flushing Systems incorporate physical security and are UL-listed and certified to NSF/ANSI 372.

The Hydro-Guard® 1200 Series System Management and Remote Telemetry (S.M.A.R.T.) The Flushing System monitors water quality conditions anywhere in the distribution system, but it is ideal for the most remote or troublesome points in the distribution network. Its advanced technology allows it to monitor conditions, and react to them, when necessary, to mitigate a condition that is outside of the utility’s acceptable range for chlorine (total, free, or combined), temperature, pH, turbidity, flow, or pressure.

The 1200 Series S.M.A.R.T. system captures water quality condition data and transmits it back to operators and managers in near-time so that water quality and distribution network maintenance decisions can be made more effectively and efficiently. Data transfers, often by way of cellular networks, can be monitored and managed in the Hydro-Guard User Interface or in SCADA.

FEATURES:

- Near-time water quality data management log

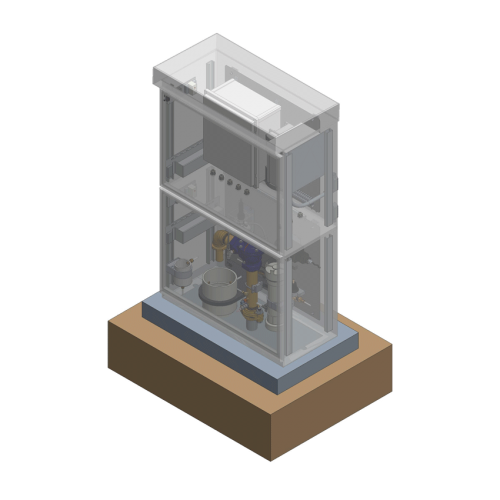

- Weather-proof, climate-controlled, and lockable protective enclosure, mounting system, and weather-proof fittings; multiple access doors for ease of use and maintenance

- Internal piping assembly is comprised of no-lead brass piping and a piloted 2” Singer Control Valve with speed control and flow adjustments1

- Monitoring – Simultaneous monitoring of multiple water quality conditions

- Mitigation – User-defined setting for flushing parameters to mitigate water quality issues

- Data Logging – Data logged incrementally for analysis and trend mapping

- Cellular remote upgrade packages optional

- 120-volt AC power and alternative power compatible

- SCADA Compatible (ModBus-TCP)

Footnote1:

In the event that flow monitoring is required, a cast valve with an integrated digital flow meter will be utilized.