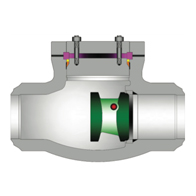

2-24″ Figure Numbers: 1695 / 1995 / 1195 / 1295 Pressure Seal Bonnet Butt Weld Ends Cast Carbon, Stainless or Alloy Steel Materials Available in all trim configurations. Other sizes available on request.

600- 2500# Pressure Seal Tilting Disc Check Valve Design Features:

- Standard trim is stellite faced seat and disc seat surfaces, and 13% chrome disc pin (API trim 5). Other trims are available on request.

- 600- 2500# Pressure Seal Tilting Disc Check Valves are full port design per ASME B16.34 Table A- 1.

- Seat faces are lapped for a smooth finish and superior sealing.

- Wall thickness per heavy wall API 600 requirements.

- Body and cap joints are accurately machined. Gasket details on page 6.

- Each 600- 2500# pressure seal tilting disc check valve is shell and seat pressure tested per industry standard API 598.

- 600- 2500# Pressure Seal Tilting Disc Check valves are suitable for service in a horizontal line with a cap vertical or in a vertical line with a flow upward.

- Weld end valves are B16.10 short pattern design. Flanged end valves are available on request and are B16.10 long-pattern design. Weld end valve dimensions are given in the table on the next page.

- Each pressure seal tilting disc check valve has a unique certification number that is traceable to the valve certification sheet which includes MTR data, pressure test, inspection result, and certificate of conformance.

- Other available options are as follows: -Alternate valve materials such as chrome and stainless steel alloys -Alternate trim materials -Drain and other auxiliary connections -NACE service -Special cleaning for applications such as oxygen or chlorine -Other options available as Specified